- September 25, 2019

- Posted by: David Marshall

- Category: Management, Manufacturing

We’ve already decided that manufacturing automation is eventually going to be a commonplace manufacturing method. But when and how much is up to each individual company. Will they embrace it quickly and try to transform the entire company? Will a new company try to build itself on manufacturing automation? Or will older, larger companies slowly enter the pool, dipping their toes for a few years before taking another baby step?

First, just remember that automation is no panacea. Switching to a fully automated process isn’t going to magically change an organization or suddenly make it a powerhouse of efficiency and productivity.

In the end, it’s a function of the leadership of the organization. How involved do they want to be in doing this? How deep do they want to dive?

Take large organizations: They can afford the infrastructure and the engineers to do all the studies before they make a decision. And they often have the capital to take a few tentative steps into automation.

But the small companies don’t have the luxury of all that overhead. They can’t afford the studies and the engineers to make sure everything will work before they pull the trigger. That means the decision falls to the leadership. They have to take ownership of the company vision and what they want to be when they grow up.

But the small companies don’t have the luxury of all that overhead. They can’t afford the studies and the engineers to make sure everything will work before they pull the trigger. That means the decision falls to the leadership. They have to take ownership of the company vision and what they want to be when they grow up.

When you’re in a capital intensive environment, that can be a very tough psychological change to make. You’ve already invested once and you want to get as much out of it as you possibly can. But after 20 or 30 years, the technology has changed, so you might have been a state of the art company at some point, but you’re not any longer.

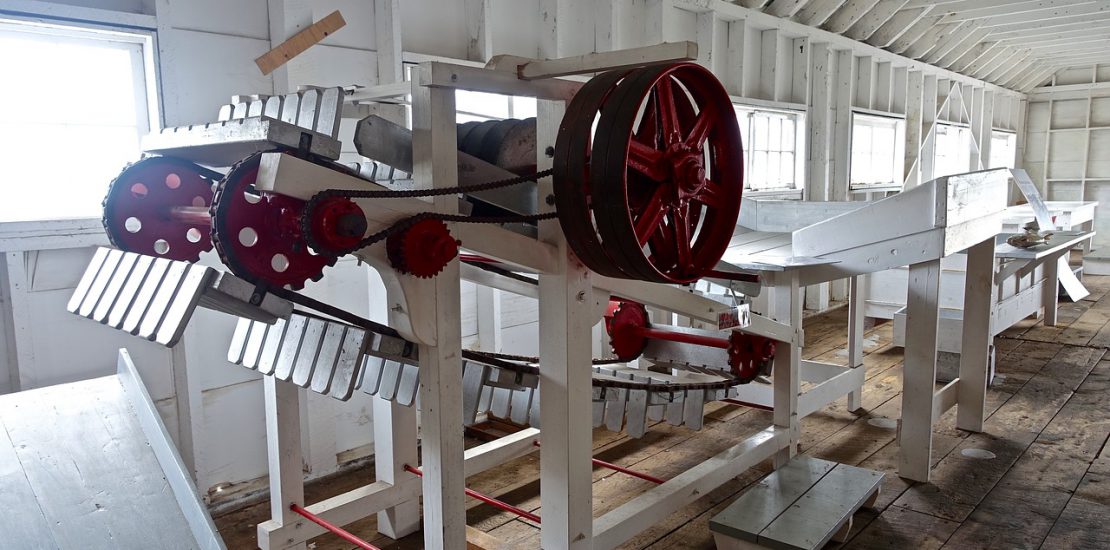

Take a molding press operation, for example. With today’s technology, those can be designed and run as a lights-out operation. But the organizations that are 30 – 40 years old paid an awful lot of money for their presses and tooling back in the ’80s. Recapitalizing that business is going to be very tough to do, particularly if they’re in a price-driven, commoditized environment.

But even while they try to squeeze another 10 years out of their presses, they’re going to reach the point where the machines are no longer viable and they’ll be behind the competitors who made the automation switch right now.

If you’ve currently got 1,000-ton presses with the tooling design to operate on those presses, you’re going to have to re-spend an awful lot of money. Then the question becomes whether you can get an ROI in the time that you need.

In larger operations, they can amortize the new machine costs over, say, 1 million units per year for 10 years, and show how they can pay for the new automatic machines. But smaller operations are never going to see that, so they’re going to have a tougher time.

That’s because when you bought the initial 1,000-ton presses, you’d typically see a payoff over 10 years, depending on your volume. Once you got your payback, you’d want to run it for a couple of decades to make some money on it. You could make updates and repairs as long as you knew you could run the machine and keep the output the same.

When I was in charge of different manufacturing operations, I always made sure we had a 5-year or 10-year migration plan. I would identify the technology that would actually add value to our processes, and then start making the move toward that goal.

For example, if I knew we were going to have to upgrade a piece of machinery because of wear and tear, I would have measurement sensors connected to the machine, look for potential interconnectivity points, and so on.

The goal was for us to start acting like we were already using the new machine: we measured wear and tear, measured output, and operated the new machine within our existing automated system. This would let us benchmark our current output and costs. Then, when we looked at new machines, we knew what levels of productivity, safety, and maintenance we had to beat. All this measurement let us figure out what those numbers had to be.

Even with a smaller overhead and without the small army of engineers that the large companies have, we were able to make educated, well-researched decisions about what was to be a difficult and expensive decision.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business. If you would like more information, please visit my website and connect with me on Twitter, Facebook, or LinkedIn.

Photo credit: Mixabeast (Pixabay, Creative Commons 0)