- December 11, 2019

- Posted by: David Marshall

- Category: Manufacturing, Productivity

Depending on which news source you read, manufacturing jobs are on the rise or they’re dropping faster than gravity. Some states are seeing major layoffs, while other states have hundreds, or even thousands, of new job openings for manufacturing labor, especially skilled labor.

The overall trend seems to be on an upward slope for a while, but despite the constant fluctuations and variations, there’s one area of manufacturing hiring that is actually seeing a shortage of labor and high demand for workers, and that’s the skilled labor market.

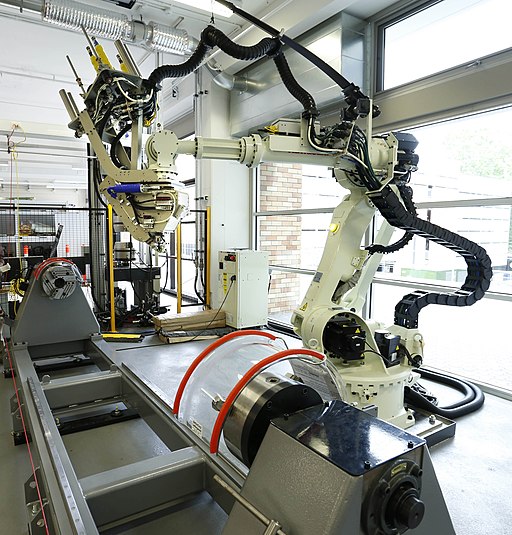

These are the jobs that deal with a lot of the new manufacturing technology we’re seeing in factories today: manufacturing automation, artificial intelligence, CNC routing, 3D printing, and even increased measurement sensors and methods.

The new technology is able to function with minimal human intervention. They can produce more with fewer errors, run longer, and work even when no one is around. That means productivity goes up even while fewer workers are producing those parts.

The new technology is able to function with minimal human intervention. They can produce more with fewer errors, run longer, and work even when no one is around. That means productivity goes up even while fewer workers are producing those parts.

While all this new technology is replacing workers in some jobs — jobs with high repetition and little variation which requires little skill — it’s also creating more opportunities in other areas.

For example, rather than operating hydraulic presses by hand, automated machines are being designed to stamp, press, and drill those same parts automatically. While that eliminated low-wage, low-skill jobs, it created the need for someone to provide maintenance and upkeep of the machines. There is also a need for skilled professionals to set up the machines for new run tickets as the old ones are completed.

As 3D printing and additive manufacturing is becoming a bigger part of the manufacturing field, factories are looking for people who know how to design items on computer software and prepare them for production, as well as people who have the skill to set up and operate the machines.

CNC routers are a big part of manufacturing operations now, and companies are looking for people with specific college degrees to be able to program the machines to actually do the operations. And while the actual operators don’t need a college degree, they often do require special training and/or certifications just to be able to operate the machines on the factory floor.

And measurement practices often require people with not only an operations mindset and experience, they also need to be conversant in statistical methods, reporting, and artificial intelligence and machine learning.

The technology of today is changing the manufacturing landscape around the world. And while people want to hold onto the jobs they used to have, it’s becoming abundantly clear that those days are never coming back and workers need to learn new technology and new skills in order to keep up.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business, including hiring skilled labor. If you would like more information, please visit my website and connect with me on Twitter, Facebook, or LinkedIn.

Photo credit: Alidarejeh (Wikimedia Commons, Creative Commons 4.0)